Revolutionizing Ready-Mix Concrete: PCE Solutions for Superior Workability, Water Reduction & Slump Retention

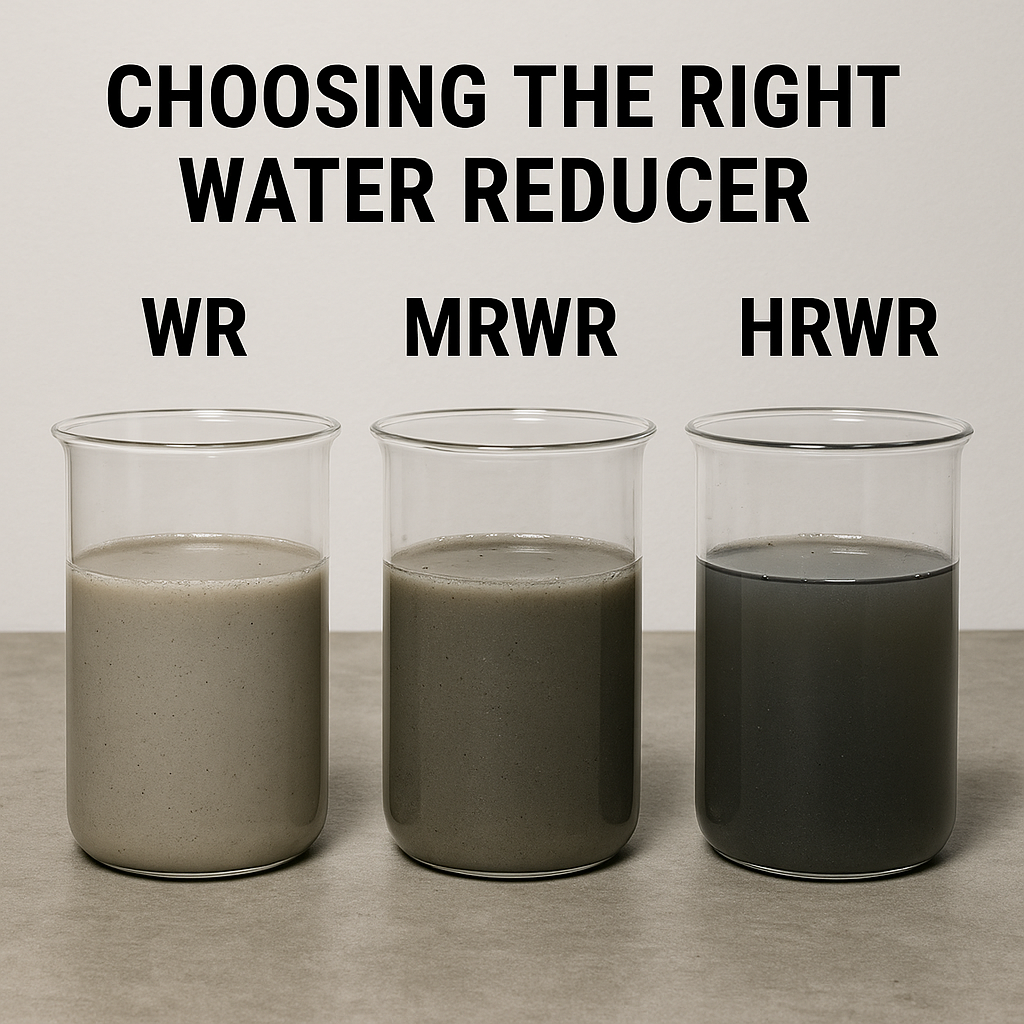

Concrete is the backbone of modern infrastructure, but the expectations from concrete today are far more demanding than ever before. Contractors and engineers need concrete that flows better, sets reliably, and retains its properties during transportation and placement. Enter Polycarboxylate Ether (PCE)—the next-generation chemical admixture that’s changing the game. At Altus Material, we specialize in