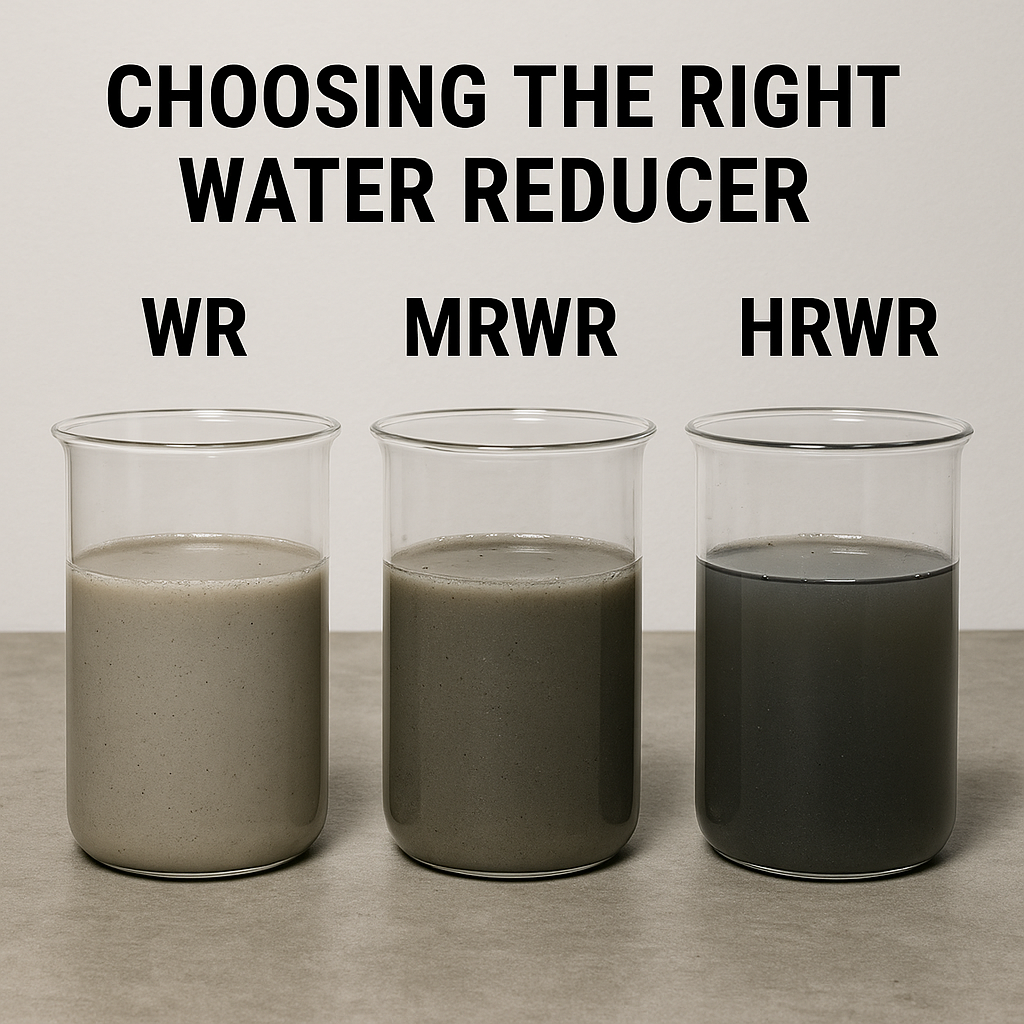

Choosing the Right Water Reducer: WR vs. MRWR vs. HRWR

In the world of concrete mix design, achieving the perfect balance between workability, strength, and durability can feel like walking a tightrope. One of the most critical tools in a formulator’s toolkit is a water reducer—a chemical admixture that helps control the water-to-cement ratio while enhancing key performance characteristics of concrete. But with different types

In the world of concrete mix design, achieving the perfect balance between workability, strength, and durability can feel like walking a tightrope. One of the most critical tools in a formulator’s toolkit is a water reducer—a chemical admixture that helps control the water-to-cement ratio while enhancing key performance characteristics of concrete. But with different types available—namely Water Reducers (WR), Mid-Range Water Reducers (MRWR), and High-Range Water Reducers (HRWR)—how do you know which one is right for your next project? This practical guide breaks down each category and walks you through how to choose the best fit based on specific job requirements.

Understanding Water Reducers and Their Purpose

At their core, water reducers are chemical admixtures added to concrete to reduce the amount of water required without affecting its consistency. The primary benefits of using a water reducer include:

- Improved compressive strength

- Enhanced durability

- Better workability at lower water content

- More cohesive and less permeable concrete

Depending on the level of water reduction desired and the application, water reducers fall into three main categories:

- Normal Water Reducers (WR)

- Mid-Range Water Reducers (MRWR)

- High-Range Water Reducers (HRWR)

Category Breakdown: WR, MRWR, and HRWR

1. Normal Water Reducers (WR)

Also referred to as Type A admixtures under ASTM C494, normal water reducers typically reduce water content by 5–10%. Derived from lignosulfonates or similar compounds, they are most useful when moderate water reduction is needed.

Best Applications:

- Residential slabs and sidewalks

- Non-critical structural elements

- Precast components where high flow isn’t necessary

Benefits:

- Cost-effective

- Improves strength and surface finish

- Moderate setting time control

Limitations:

- Not ideal for high-flow or high-strength concrete

- Less effective in very low water-cement ratio mixes

2. Mid-Range Water Reducers (MRWR)

MRWRs are a relatively newer class of admixtures designed to bridge the gap between WR and HRWR. These admixtures typically reduce water content by 6–12%. They are often formulated using modified lignosulfonates or synthetic polymers.

Best Applications:

- Floor slabs requiring improved finishability

- Indoor applications where consistent workability is key

- Ready-mix operations needing slump retention

Benefits:

- Increased workability compared to WR

- Better pumpability for longer transport distances

- Controlled set times for extended working window

Limitations:

- Not suitable for extremely high-performance mixes

- Incompatible with some supplementary cementitious materials if not properly tested

3. High-Range Water Reducers (HRWR)

Known commonly as superplasticizers and categorized as Type F (or G with retardation), HRWRs provide water reduction in the range of 12–30%. These powerful modifiers—often based on polycarboxylate ethers (PCEs)—are great for producing high-slump concrete without increasing water content.

Best Applications:

- High-strength concrete (HSC) and self-consolidating concrete (SCC)

- Precast/prestressed beams and panels

- Architectural concrete needing superior surface finish

- Projects requiring fast-track construction or early strength gain

Benefits:

- Superior water reduction and flowability

- Highly compatible with low water-cement ratio designs

- Enhanced long-term durability and strength

Limitations:

- Can cause segregation if not used correctly

- More expensive than WR and MRWR

- Requires careful dosage control and compatibility testing

How to Choose the Right Water Reducer

1. Consider Project Requirements

Start by identifying what the project demands. For example:

- Do you need high early strength? → Consider HRWR.

- Is cost a constraint, but you still need improved workability? → MRWR might be a fit.

- Is the project a simple residential slab? → WR could suffice.

2. Evaluate Desired Water Reduction

| Admixture Type | Typical Water Reduction |

|---|---|

| WR | 5–10% |

| MRWR | 6–12% |

| HRWR | 12–30% |

3. Check Compatibility with Other Mix Ingredients

Water reducers must behave consistently with cement type, supplementary cementitious materials (like fly ash or slag), and any other admixtures (retarders, accelerators, air entrainers).

- Always perform compatibility and slump retention testing in the lab before full-scale use.

- Some HRWRs can be sensitive to specific cement chemistries and may require adjustment.

4. Assess Environmental and Climatic Conditions

Weather can affect how water reducers perform:

- In hot climates, MRWRs and HRWRs with set-retarding properties help control hydration timings.

- In colder conditions, accelerators or modified WRs may be needed to maintain productivity.

5. Evaluate Long-Term Performance Needs

Is durability—resistance to freeze-thaw cycles, sulfate attack, or chloride ingress—a concern? HRWRs paired with a dense, low water-cement ratio concrete often provide the best long-term resilience.

Pro Tips for Using Water Reducers Effectively

- Test First: Always trial concrete mixes in a lab setting before construction phase begins.

- Monitor Slump Loss: Choose admixtures with consistent slump retention to avoid re-dosing onsite.

- Avoid Overuse: Excessive dosing of HRWR can cause segregation or delayed set times.

- Optimize Dosage: Follow manufacturer guidelines and refine dosage based on mix performance.

Conclusion: Making the Right Choice Pays Dividends

Choosing the right water reducer isn’t just about cutting water content—it’s about tailoring your concrete mix to meet specific structural and performance goals. Whether you’re dealing with a simple driveway or a high-rise, the proper selection between WR, MRWR, and HRWR can mean the difference between average and exceptional concrete.

Normal water reducers offer a cost-effective solution for everyday applications. Mid-range water reducers provide flexibility and improved workability for general construction. For the most demanding projects, high-range water reducers deliver maximum performance when carefully handled.

By understanding the nuances of each category and aligning them with project demands, you’ll ensure concrete that’s easy to place, durable under stress, and cost-effective in the long run.